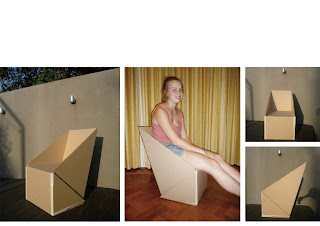

I was very nervous and to be honest quite unsure as to wether my final design would work. As my chair basically used up the entire piece of xanita, this meant that I was unable to get it laser cut at the workshop but instead would have to cut it myself. To try and make life a little easier I printed out my autocad plan on 25 A3 pages and stuck them onto the xanita with masking tape. Having my lines to guide me I started to cut. Having been cutting on my hands and knees for the past 6hrs I was tired, sore and running out of patience. Wether it was a mix between this, the fact that I just changed blades or that I had left the xanita in the glaring sun for a good part of the day, I am unsure, but as I was doing some of my 45degree cuts as well as cutting through to the outer layer the material ripped- and well that was that. I was quite upset, as I had not ONCE cut through the material on my practice piece. In the end I had to use masking tape to hold some of the edges together. The join, which was meant to bolt down the armrest, also snapped off at the fold, so I don’t advise leaning back! All in all I was actually quite happy with my design, as I believe that with another piece of xanita my chair would be “hole proof” and do it’s job more proficiently.